Technology

With Peterson Instrument Co’s innovative technology, beautiful analogue instruments can now be driven by a vehicle’s CAN bus system, interfacing with any CAN bus ECU, PDM/PDU or Electric Vehicle system. There are two approaches to using our technology with your gauges, depending on your requirements:

01

Peterson Instrument Co. Instrument Control Unit

With only one Control Unit, a CAN bus input drives the entire dashboard of existing analogue gauges. We can either replicate the standard form, or offer different parameters, such as converting a tachometer to kWs or the addition of warning lights and indicators. Gauges can be converted to stepper motor drive, or the control unit can drive existing moving coil, bi-metallic, or frequency input gauges.

02

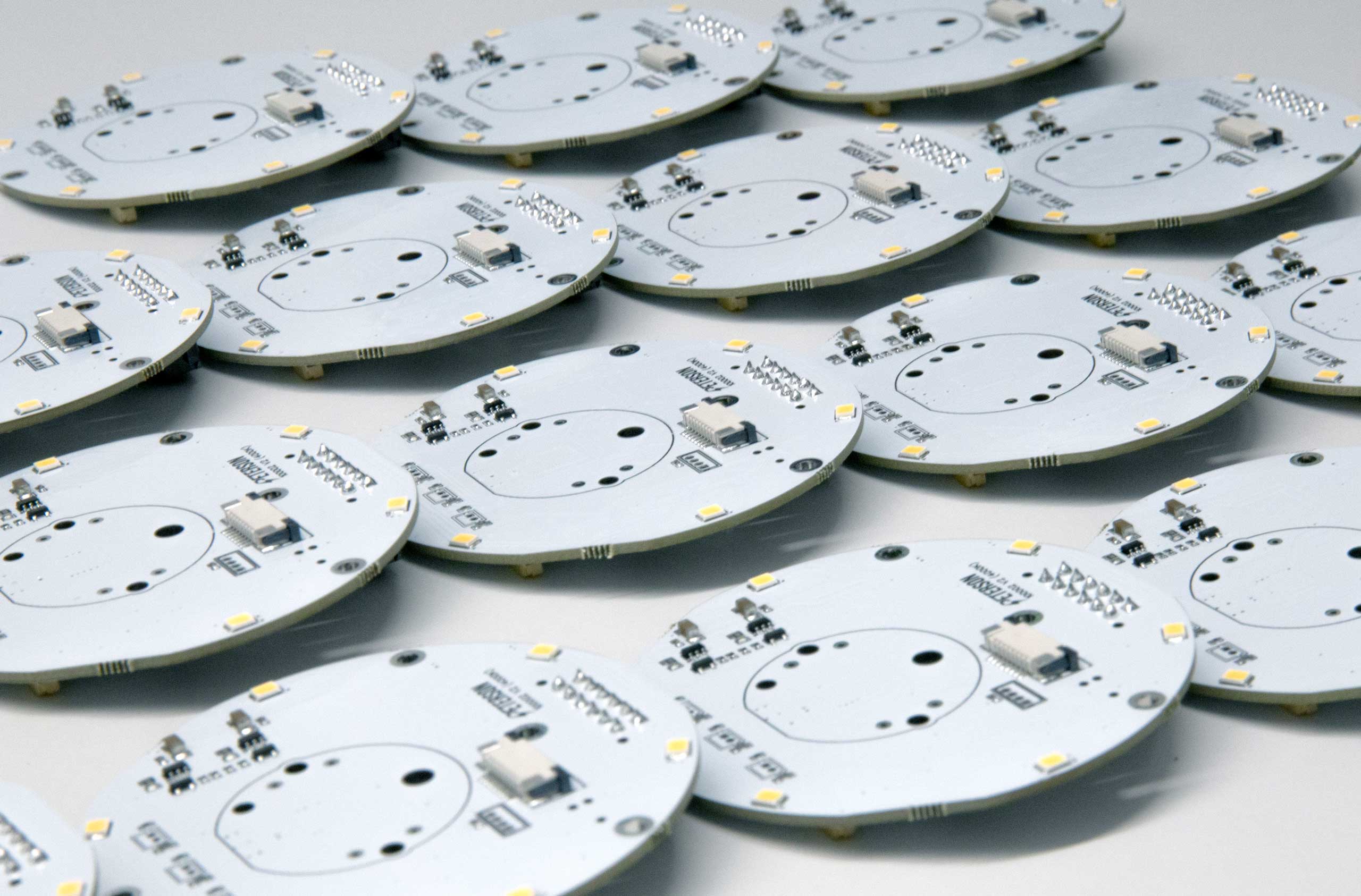

Peterson Instrument Co. modular in-gauge electronics

Our electronics are individually fitted to the inside of each of either ‘upcycled’ instruments or to instruments we have manufactured for your project. A space-saving solution, our modular electronics offer enhanced reliability and configurability with unlimited choices.

Multi-function configurable hardware offers the following benefits:

- Utilisation of both permanent and switched live inputs to remove the need to ‘zero’ the gauge on startup, offering an OEM feel to the product. Gauge start-up sweeps are available on request.

- Programmable warning lights with brightness control and night-time dimming to reduce undesirable night-time glare that a standard warning light gives.

- Illumination brightness adjustment for different gauge types, which can be configured for CAN bus or a 12v input, with optional dimming via CAN bus.

- OLED display parameters such as odometer, trip and gear selection via CAN bus or internal calculation, fully compatible with the latest PDM/PDU/VCUs.

- Dynamic tuning of the gauge movement characteristics. For example, temperature gauge dead-banding can resemble your modern OEM vehicle and tachometer pointer damping can enhance the feel of the car, whether it is a fast-revving race-car or a modern Restomod cruiser.

We offer high-quality, reliable products and the utilisation of modular architecture enables us to gather many miles of road-testing across the entire Peterson Gauge fleet. However, due to the complexity of these systems, we work exclusively business-to-business with trained installers.

We will ask for a full DBC file of your system, which is often provided by your ECU, PDM or EV provider. Providing full technical backup with our product range, we provide customers with a range of analytical and problem-solving tools, with dealer level adjustment for regulatory parameters, such as odometer and speed offsets.

Adjustments and changes can all be made via the vehicle’s CAN bus system, using Peterson Instrument Co.’s application software, without the need to disturb or remove the gauges.

Our electronics are designed to comply with the UNECE R10 automotive EMC standards making them perfect for Niche Vehicle Manufactures who may be required to conduct full-vehicle testing to sell internationally.